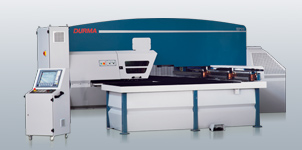

Machine Tools » Punching presses » TP series

TP series

TP series

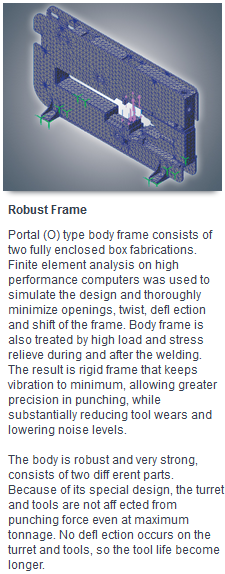

- Small, medium and large format sheet processing Punching,forming,tapping, and wheel technology capabilities Stress relieved O frame

- Flexible turret configurations to elimimate tool setups

- Auto lubrication of moving parts

- Rigid guides

- One of the best controller with functionality & flexibility

- Powerful control with user friendly CAD-CAM Software

- Programmable sheet clamping system decreases set-up times and scrap ratio Automation can be easily integrated for efficient and lean operations while also increasing operator safety and as well as decreasing opertor fatique.

Product resources

A few optional accessories

- Light barriers for CE Additional clamps

- Table (brush&ball)

- Tools, Tool holders, reducers

- CAD-CAM SW Second activator (dongle)

- SW for Autonesting, Wheel and Tapping tools

- Sheet deformation alert switch Turret cover for perforated sheets Vacuum slug remover

- Workchute

- Automatic lubrication for the machine Air condition for electrical box Additional oil cooler

- Loading- Unloading preparation Loading- Unloading system Additional table

- Special table

- Transformator

- UPS for machine ( 30KvA - 10 min ) Additional allignment tool

Standards accessories

- CE norm

- Foot pedal

- CAD-CAM software and activator

- Control unit: Siemens Sinumerik 840 D SL

- Operating system: Windows 7

- Automatic clamp positioning

- Network, Ethernet communication

- Programming on the control panel

- Automatic tool lubrication

- Movable scrap box

- Brush table

- Oil cooler

- USB drive

- Repositioning of X axis

- Alignment tools for index station (C+B station)- TP9

- Alignment tools for index station (D station)- TP93, TPL93, TP123, TP Servo, TPL Servo)

- Manual nesting

- Warning lamp

- Light barrier

- Maintanance and instruction manual

Similar products on stock:

New

Durma TPL93 - Punching presses

Price upon inquiry

Images

Light barrier protection, control unit Siemens Sinumerik 840, 4 automatic pneumatic clamps, Foot pedal, CAD / CAM software key, programming from the control unit, network software for PC connection, automatic lubrication of tools, UPS uninterruptible power supply for control unit, mobile waste bin, brush table, oil cooling, USB drive, Webcam for service, Operation and maintenance manual, X axis repositioning, upper tool magazine with fixing screws, adjustment set for D index station + Automatic nest calculation and wheel tool programing+Sheet damege warning

+36 62 428 800 (Office)

+36 62 428 800 (Office) +381 24 851 133

+381 24 851 133