Machine Tools » Notchers » FN / VN series

FN / VN series

FN / VN series

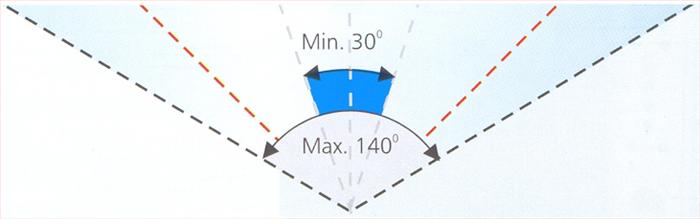

- Durma Corner Notchers have a rigit construction with a solid machined table. T-Slots have been machined in the table for fast and accurate positioning of gauge stops and protractor guides. The operator can adjust the angle of notch from 30 to 140 degrees easily and quickly via hand viels wheels located on each side of the machine.

- The automatic blade adjustment feature assures high quality cuts on varied thickness and types of material.There are three upper and four lower hydraulics cylinders that create a rigid structure for accurate for and repeatable notching.

- The measuring scales have been positioned below the work service to prevent wearing of dimensional readouts over time.

Product resources

Standards accessories

- Blade suitable for cutting mild or stainless steel

- Easy to operate

- Hand and foot control

- T-slotted table with recessed measuring scales

- Automatic setting of blade clearance

- CE-norm for EU

Similar products on stock:

New

Durma VN 2006 - Notchers

Price upon inquiry

New

Durma VN 2004 - Notchers

Price upon inquiry

New

Isitan MN 3 - Notchers

List price (w/o tax): 2 650 €

New

LFSS HNM 6 VP - Notchers

List price (w/o tax): 21 000 €

Images

motor: 4kW, cutting angle: 30-tól 140°-ig, cutting length: 200x200 mm, max. cutting per minute: 30, oil tank capacity: 35 l, max. working pressure: 200 bar, extra punch and die (6mm)

+36 62 428 800 (Office)

+36 62 428 800 (Office) +381 24 851 133

+381 24 851 133